Product Search

You can find all the machines we manufacture by typing in the search box below:

Welcome

Stone mills for whole wheat / grain flour are back as Başay Stone Age Mills.

Classical milling in accordance with the modern age is once again ... Rediscover the taste and high nutrition of traditional flours that have been forgotten.

Yeni Modüler Un Değirmeni

Modüler sistem. Temizleme modülüde eklenebilir.

Yeni Modüler Taş Un Değirmeni

Modüler sistem. Temizleme modülüde eklenebilir.

DVT3W

2 ton/saat Un üretim tesisi.

TDT80

Tam Buğday Unu Mini üretim tesisi.

TDT4

2 ton/saat Tam buğday unu üretim tesisi.

5S Manufacturing

A regular, tailor-made production system is applied.

FCSS

All machines are manufactured as Standard, Food Contact Surface Stainless (FCSS) or completely Stainless according to your request Shing Mill Plant

DVT4

DVT4 Başay Vertical Roller Fully Washing Mill Plant

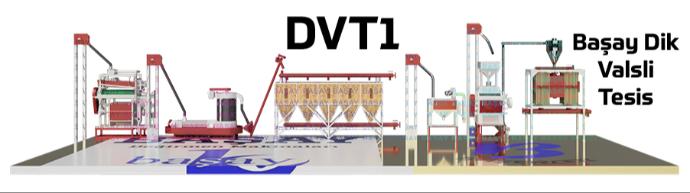

DVT1

DVT1 Başay Vertical Roller Fully Washing Mill Plant

DVT3

DVT3 Başay Vertical Roller Dry System Mill Plant

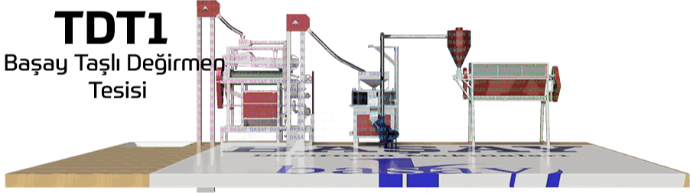

TDT1

TDT1 Basay Mill Stone Plant

Sieve Cleaning

|

|

BBT1TF Wheat Cleaning Selector with Brush and Trieur

|

|

|

BOT1 Grain Pre-Cleaner with Fan and Sieves

|

|

|

BCS1 Grain Separator

|

Water Cleaning

It removes dust and dirt from the wheat by washing it with water, separates most stones and discharges its water by shaving gently. It removes dust and dirt from the wheat by washing it with water, separates most stones and discharges its water by shaving gently. |

BDY1 Vertical Wheat Washer and Dryer

|

Buğdayın akış kontrolü su kullanarak nemlendirilmesini sağlar. Buğdayın akış kontrolü su kullanarak nemlendirilmesini sağlar. |

BCT1 Intensive Dampener

|

After wheat is washed, it stays in this wood stores to naturally evaporate water. After wheat is washed, it stays in this wood stores to naturally evaporate water. |

BTA5000 Wheat Dampening Store 5 Tons

|

It washes the wheat with water, removes the dust and dirt, peels off the outer skin gently. It washes the wheat with water, removes the dust and dirt, peels off the outer skin gently. |

BYY1 Yatık Yıkama ve Soyma

|

Dehuller

For gentle peeling of the outer skin of the wheat. It is recommended to be used after washing and tempering. For gentle peeling of the outer skin of the wheat. It is recommended to be used after washing and tempering. |

BKS1 Intensive Scourer / Shell Peeler

|

For peeling the outer skin of moistened wheat. It can be used in the peeling process of moist / wet grains. For peeling the outer skin of moistened wheat. It can be used in the peeling process of moist / wet grains. |

BTC1 Drum Peeler

|

It is used for separating the grains slightly moistened with a fan. It is important in the production of bulgur. It is used for separating the grains slightly moistened with a fan. It is important in the production of bulgur. |

BYC 1 Compact Wheat Shell Remover

|

Lightly peel the outer skins of the wheat. Lightly peel the outer skins of the wheat. |

BES1 Light Horizontal Shell Scourer

|

It provides separation of the grain shell. The bran / membrane / shell is easily ejected with the fan. Specially developed for Siyez Wheat and triticulum dicoccum (Emmer wheat). It provides separation of the grain shell. The bran / membrane / shell is easily ejected with the fan. Specially developed for Siyez Wheat and triticulum dicoccum (Emmer wheat). |

BKS50S Siyez Scourer / Shell Peeler

|

Stone Mill

|

|

BTD120 1200mm Classic Stone Mill

|

|

|

BTD110 1100mm Classic Stone Mill

|

|

|

BTD80 800mm Classic Stone Mill

|

It is the ideal mill for whole wheat and grain flour. Using 500mm stone, it turns the grain into flour in one operation. Rotating Bottom. It is the ideal mill for whole wheat and grain flour. Using 500mm stone, it turns the grain into flour in one operation. Rotating Bottom. |

BTD50 500mm Classic Stone Mill

|

It is the ideal mill for whole wheat and grain flour. Using 150mm stone, it turns the grain into flour in one operation. Rotating Bottom. It is the ideal mill for whole wheat and grain flour. Using 150mm stone, it turns the grain into flour in one operation. Rotating Bottom. |

BTD15 150mm Mini Stone Mill

|

Roller Mill

|

|

BDV1 BAŞAY™ Vertical Roller Mill

|

|

|

BDV80 Vertical Roller Mill/LİSO

|

|

|

BYV1 Horizontal Roller Mill

|

Crusher With Millstone

|

|

BTD60D 600mm Vertical Stone Mill

|

|

|

BTD50D 500mm Vertical Stone Mill

|

|

|

BTD40D 400mm Vertical Stone Mill

|

Plansifter

|

|

BSE214 Two Passage 14 Layers Plansifter

|

|

|

BSE111 Single Passage 11 Layers Plansifter

|

|

|

BSE15 Single Passage 5 Layers Plansifter

|

Rotary Sifter

|

|

BDE60 Rotary Drum Sieve

|

|

|

BDE43 Rotary Drum Sieve

|

Crusher With Millstone

|

|

BTD60D 600mm Vertical Stone Mill

|

|

|

BTD50D 500mm Vertical Stone Mill

|

|

|

BTD40D 400mm Vertical Stone Mill

|

Hammer Mill

|

|

BBK 3216 Hammer Mill(32 blades 160mm Sieve)

|

|

|

BBK 3228 Hammer Mill (32 blades 280mm Sieve)

|

With Rotary Hammers, it shears the product in the desired size according to the sieve type. Standard 32 Blades 380 Volt. With Rotary Hammers, it shears the product in the desired size according to the sieve type. Standard 32 Blades 380 Volt. |

BBK 3228 Hammer Mill with Fan (32 blades 280mm Sieve)

|

|

|

|

Bıçaklı/Çekiçli Kırıcı İle Eleme |

|

| Döner Bıçaklar / Çekiçler ile ürünü elek tipine göre istenilen ölçüde kırma yapar. Ürünler sallamalı elek ile elenerek ayrıştırılır. | BBK3216ES Bıçaklı Kırıcı Değirmen 16cm Elekli ve Eleme Sistemli |

Crusher and Sieve with Mill Stones

|

|

BBS6KES Bulgur Crusher and Sieve with 600mm Stone

|

|

|

BBS5KES Bulgur Crusher and Sieve with 500mm Stone |

It crushes with 400mm Millstone. It is the ideal crushing form for the production of bulgur. It crushes with 400mm Millstone. It is the ideal crushing form for the production of bulgur. |

BBS4KES Bulgur Crusher and Sieve with 400mm Stone |

Crusher with Roller Mill

|

|

BBS6VKES Başay Desa™ Bulgur Crusher and Sieve

|

Mashing/flake with Roller Mill

|

|

BTE4000 Flake

|

|

|

BTE2000 Flake

|

|

|

BTE2300 Flake

|

Mashing with Hammer Mill

|

|

BBK3216SM Tomato Paste Machine

|

|

|

BSM1 Tomato Paste 220V

|

|

|

BSM3 Tomato Paste 380V

|

Başay AR & GE Tasarımı ile domates ve biber salçası yapmak için tamamen paslanmaz. Başay AR & GE Tasarımı ile domates ve biber salçası yapmak için tamamen paslanmaz. |

BBK3216SMR Bıçaklı Domates Ezme Salça Makinası Helezonlu |

Mobile Mashing/ Crushing (With Tractor Shaft Power)

|

|

BTE2000S Shaft Flake

|

|

|

BRS1 Mashing/ Flake, Stone Crushing Mobile Trailer System

|

Grain Seed Cleaning

|

|

BTT643 Seed Cleaning with 3 Sieve |

|

|

BTT644 Seed Cleaning with 4 Sieve

|

Wheat Seed Cleaning

|

|

BTT2T Wheat Seed Cleaning

|

|

|

BTT1F Seed Cleaning |

Seed Spraying

|

|

BTI1 Başay Desa™ Dry Powder Spraying Machine

|

Top Rotary Mill Stones

|

|

BDT120 Mill Stone 1200mm

|

|

|

BDT110 Mill Stone 1100mm

|

|

|

BDT100 Mill Stone 1000mm

|

|

|

0 382 215 1363 or Whatsapp: +90 531 819 0791 |

Bottom Rotary Mill Stones

|

|

BDT80 Mill Stone 800mm

|

|

|

BDT7080 Mill Stone 700x800mm

|

|

|

BDT50 Mill Stone 500mm

|

|

|

BDT15 Mill Stone 150mm

|

|

|

0 382 215 1363 or Whatsapp: +90 531 819 0791 |

Vertical Rotary Mill Stones

|

|

BDT60D Mill Stone 600mm

|

|

|

BDT50D Mill Stone 500mm

|

|

|

BDT40D Mill Stone 400mm

|

|

|

0 382 215 1363 or Whatsapp: +90 531 819 0791 |

Stone Tooth Hammer

|

|

BDT1 Stone Tooth Hammer

|

Vertical Handling Machines

|

|

BBT100 Bucket Elevator |

Angle Conveying Machines

|

|

BBH100 Screw Conveyor

|

It allows products to be transported horizontally at an angle and to be transmitted without impact. It allows products to be transported horizontally at an angle and to be transmitted without impact. |

BKB80 Conveyor Band

|

Air Transport Machinery.

|

|

BEF405 Fan

|

|

|

BTS76 Cyclone

|

Grain and Feed Mixer

|

|

BYM1 Grain andFeed Mixer |

Stone Flour Mill System

It is the most suitable system for Organic Whole Wheat Flour Processing, developed by our leading company in stone mills and millstones.

Vertical Roller Mill

It is the system developed by our leading company in vertical roller mills.

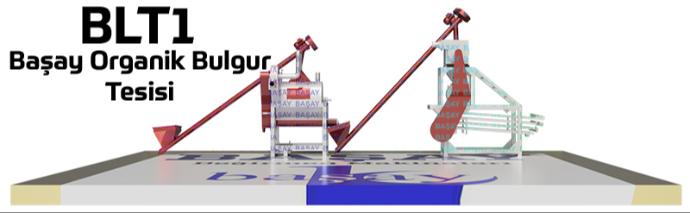

Stone Bulgur Mill (Mill Stone)

It is the most suitable system for Organic Bulgur Processing, developed by our leading company in stone mills.

It is a Başay R&D product that allows the wheat to be cleaned by Air, Sieving and Shaving and to be separated from foreign seeds with a trieur.

It is a Başay R&D product that allows the wheat to be cleaned by Air, Sieving and Shaving and to be separated from foreign seeds with a trieur.

It performs general cleaning of cereals with fan and sieve system.

It performs general cleaning of cereals with fan and sieve system.

For removing wheat from foreign materials. Helps to remove wheat from garbage, straw, coarse, small and fine seeds. Vibration and level of the sieve system can be adjusted

For removing wheat from foreign materials. Helps to remove wheat from garbage, straw, coarse, small and fine seeds. Vibration and level of the sieve system can be adjusted It is the ideal mill for whole wheat and grain flour. Using 1200mm stone, it turns the grain into flour in one operation. Rotating Top.

It is the ideal mill for whole wheat and grain flour. Using 1200mm stone, it turns the grain into flour in one operation. Rotating Top. It is the ideal mill for whole wheat and grain flour. Using 1100mm stone, it turns the grain into flour in one operation. Rotating Top.

It is the ideal mill for whole wheat and grain flour. Using 1100mm stone, it turns the grain into flour in one operation. Rotating Top. It is the ideal mill for whole wheat and grain flour. Using 800mm stone, it turns the grain into flour in one operation. Rotating Bottom.

It is the ideal mill for whole wheat and grain flour. Using 800mm stone, it turns the grain into flour in one operation. Rotating Bottom. It is designed for medium capacity flour mills. It can also work individually. It produces flour with 4 steel cylinders.

It is designed for medium capacity flour mills. It can also work individually. It produces flour with 4 steel cylinders. It is designed for medium capacity flour mills. It can also work individually. It produces flour with 2 steel cylinders.

It is designed for medium capacity flour mills. It can also work individually. It produces flour with 2 steel cylinders. It is designed for high capacity flour mills. It can also work individually. It produces flour with 4 steel cylinders.

It is designed for high capacity flour mills. It can also work individually. It produces flour with 4 steel cylinders. It crushes the grain by using 600mm millstones.

It crushes the grain by using 600mm millstones. Used to separate bran from ground flour. It has 2 passages. There are 14 screening layers in each passage. (It can be made in 11 floors).

Used to separate bran from ground flour. It has 2 passages. There are 14 screening layers in each passage. (It can be made in 11 floors). It is used to separate bran from ground flour. It has a single passage. There are 11 screening layers.

It is used to separate bran from ground flour. It has a single passage. There are 11 screening layers. It is used to separate bran from ground flour. It has a single passage. There are 5 screening layers.

It is used to separate bran from ground flour. It has a single passage. There are 5 screening layers. It is the most ideal sieve type for stone mill. It is used to separate bran from ground flour. The drum is 600mm.

It is the most ideal sieve type for stone mill. It is used to separate bran from ground flour. The drum is 600mm.

With Rotary Hammers, it shears the product in the desired size according to the sieve type. Standard 32 Blades 380 Volt.

With Rotary Hammers, it shears the product in the desired size according to the sieve type. Standard 32 Blades 380 Volt. Crushing is done with specially opened teeth on the Roller Mill (Steel Cylinder). It can be used in the production of bulgur.

Crushing is done with specially opened teeth on the Roller Mill (Steel Cylinder). It can be used in the production of bulgur. It mashes/crushes the grain with 4 pieces of 1000mm roller mills.

It mashes/crushes the grain with 4 pieces of 1000mm roller mills.  It mashes/crushes the grain with 2 pieces of 1000mm roller mills.

It mashes/crushes the grain with 2 pieces of 1000mm roller mills. It mashes/crushes the grain with 2 pieces of 3000m roller mills.

It mashes/crushes the grain with 2 pieces of 3000m roller mills. With Başay R & D Design, it is for crushing the vegetables as a whole. It is completely stainless steel.

With Başay R & D Design, it is for crushing the vegetables as a whole. It is completely stainless steel. Mashing machine for tomato paste production (100-400 kg).

Mashing machine for tomato paste production (100-400 kg). Mashing machine for tomato paste production (400-1000 kg).

Mashing machine for tomato paste production (400-1000 kg). It mashes/crushes the grain with 2pieces of 800mm roller mills. Takes its movement from the tractor shaft.

It mashes/crushes the grain with 2pieces of 800mm roller mills. Takes its movement from the tractor shaft. Mashıng/flaking with steel roller, Crushing with millstone. Complete Mobile System with Bucket elevator and Trailer

Mashıng/flaking with steel roller, Crushing with millstone. Complete Mobile System with Bucket elevator and Trailer  It is used for cleaning various grains and classifying them as seeds. It is a 3-sieve system.

It is used for cleaning various grains and classifying them as seeds. It is a 3-sieve system. It is used for cleaning various grains and classifying them as seeds. It is a 4-sieve system.

It is used for cleaning various grains and classifying them as seeds. It is a 4-sieve system. It is used for cleaning wheat and classifying it as seed. Trieur and fan.

It is used for cleaning wheat and classifying it as seed. Trieur and fan. It is used for cleaning wheat and classifying it as seed. Trieur and fan.

It is used for cleaning wheat and classifying it as seed. Trieur and fan. It ensures that the surface of the grains is sprayed with powder pesticide and prepared for seed planting.

It ensures that the surface of the grains is sprayed with powder pesticide and prepared for seed planting. Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 1200mm.

Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 1200mm. The desired size of millstone is produced. It is enough to specify the dimensions.

The desired size of millstone is produced. It is enough to specify the dimensions. Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 800mm.

Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 800mm. Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 800mm and 700mm.

Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 800mm and 700mm. Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 150mm.

Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (upper and lower stone) with a diameter of 150mm.  Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (right and left stones) with a diameter of 60cm.

Our BAŞAY DESA abrasive millstones, which have been produced since 1979, are formulated for whole grain production. The basis of the stone is the 18th century German state of Bavaria. It is 1 set (right and left stones) with a diameter of 60cm.  Special cast steel-tipped (diamond) toothing hammer for grinding the surface of millstones and smoothing the channels.

Special cast steel-tipped (diamond) toothing hammer for grinding the surface of millstones and smoothing the channels. It allows the products to be raised upright to the desired height.

It allows the products to be raised upright to the desired height. It allows products to be transported horizontally at an angle.

It allows products to be transported horizontally at an angle. Allows the products to be transported by the air generated by the fan.

Allows the products to be transported by the air generated by the fan. Separates the flour and air mixture.

Separates the flour and air mixture. It mixes grains with spiral and mixer blades.

It mixes grains with spiral and mixer blades.